End mills are widely used in various machining. Especially,ball end mills are in the widest use to create a variety of curved surfaces. In recent years, high speed milling has been widely noticed in the light of machining efficiency. However, tool wear and breakage are becoming conspicuous with high speed milling. Thus, demands for tools suitable for high speed milling are increasing.

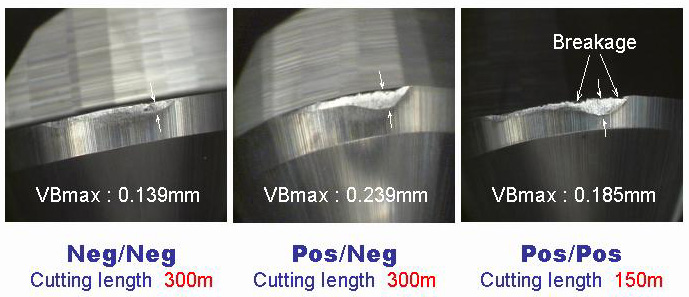

This study deals with investigating the influence of the cutting edge shape of ball end mill, changing the rake angle and helix angle. Four kinds of ball end mills were designed and fabricated by use of 5-axis control CAM software. From the cutting experiments, it is found that the ball end mill with negative rake angle and helix angle (Neg/Neg) is most suitable for high speed milling.