Metal Mold Manufacturing of Fresnel Lens by Use of Micro Grooving Technology

Nuttaphong SORNSUWIT,Yoshimi TAKEUCHI,Kiyoshi SAWADA and Toshio SATA

JSME International Journal Series C, Vol. 43 No.1 March 2000, pp.164-169

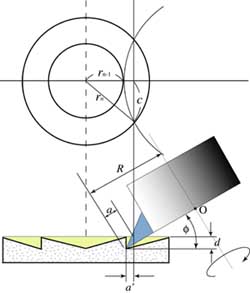

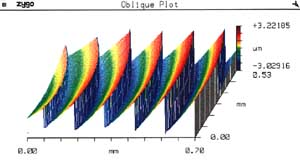

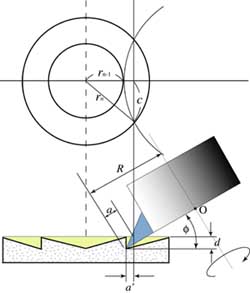

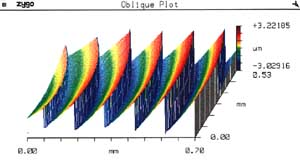

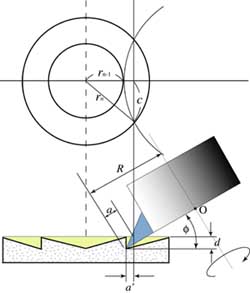

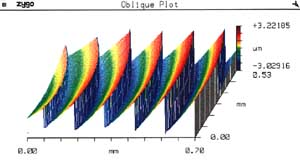

The study deals with cutting of metal for a tiny Fresnel lens which is composed of circular micro grooves.Conventional methods such as pholithography and cutting by a lathe often lead to the burr generation due to a reduction of cutting speed, especially at the center of lens, and to low surface quality such as step-like croos-section of groove by photolithography. The employment of a rotational diamond cutting tool is expected to eliminate the above problems. Thus, a workpiece of Fresnel lens is set on the main spindle of a lathe-type ultraprecision milling machine, which has the positioning accuracy of 1 nm. The diamond cutting tool is rotated by a high speed air turbine spindle. According to the cutting experiment, no burr was found at the edge of grooves, and the surface roughness of a slope in the groove was 80 nm(Rmax). The cross section of lens groove is slightly curved due to the unique way of cutting, which made a profile of lens get closer to the ideal one.

[Takeuchi Lab. Home Page]

[Takeuchi Lab. Home Page]

2000.9.28 by N.Sornsuwit

[Takeuchi Lab. Home Page]

[Takeuchi Lab. Home Page]